By Madeline Armstrong

In the last year, Northrop Grumman and the U.S. Navy have made progress on a multi-decade project to clean up a highly toxic chemical plume that has contaminated groundwater in Bethpage, South Farmingdale, Levittown and Seaford dating back years, according to officials.

The plume emanated from the site of the former Northrop Grumman-Navy aircraft manufacturing plant that operated in central Bethpage during the mid-20th century. The Navy owned part of the property.

Grumman recently entered an agreement with the New York State Department of Environmental Conservation to remediate the plume. “Under this agreement,” said Edward Hannon, Northrop Grumman project director, “the company, in partnership with the state, will take additional measures that further our extensive efforts to address impacts to soil and groundwater from historical operations supporting our national defense.”

According to the agreement, Grumman will begin work in the area of Hempstead Turnpike and the Seaford-Oyster Bay Expressway. Additionally, six vertical borings will be drilled to collect and analyze groundwater from six locations. They will be used to determine the sites for extraction wells to remove chemical contamination from the soil. “This is very similar to the work we are executing at other locations,” Hannon said, “and we will continue to actively communicate with residents, business owners and local leaders on our activities.”

Although the majority of the plume resides in Bethpage, it has also affected South Farmingdale throughout the years. According to Frank Koch, the South Farmingdale Water District superintendent, officials first found 1,4-dioxane in the groundwater three years ago. 1,4-Dioxane is among the contaminants that has been proven to result from the former Northrop Grumman-Navy plant, along with trichloroethylene (TCE).

The groundwater was treated, and the district had to pay for it out of its budget. Under the consent decree between the state, Northrop Grumman and the Navy, affected water districts will be reimbursed for funds spent on groundwater treatment. Both the South Farmingdale and Bethpage water districts have been refunded for money spent to treat contaminated groundwater in the past.

“There’s $12.5 million that’s supposed to go to an extraction well if needed north of our wells, or if the plume is overwhelming, a drinking water well over South Farmingdale for additional treatment,” Koch said.

Northrop Grumman, formerly Grumman Aircraft Engineering Corporation and later Grumman Aerospace, released an array of potentially cancer-causing chemicals at its 635-acre Bethpage manufacturing plant during the 1940s and ’50s. The Navy owned more than a hundred acres of the property and leased them to Grumman.

Among other substances, hazardous waste included chromium, polychlorinated biphenyls (PCBs) and volatile organic compounds, according to a 2015 DEC report. Those substances, the DEC said, could be found in the chlorinated solvents used to clean or degrease machine parts.

Contamination at the former plant, which operated from 1930 to 1994, was first discovered in the 1970s, when Grumman employees noticed “an unusual taste and odor emanating from water faucets located at the site,” according to the Bethpage Water District. Grumman had its own well system, separate from the district.

More than $200 million has already been spent to clean up the plume, and experts estimate it could take another $100 million to $300 million to finish the job.

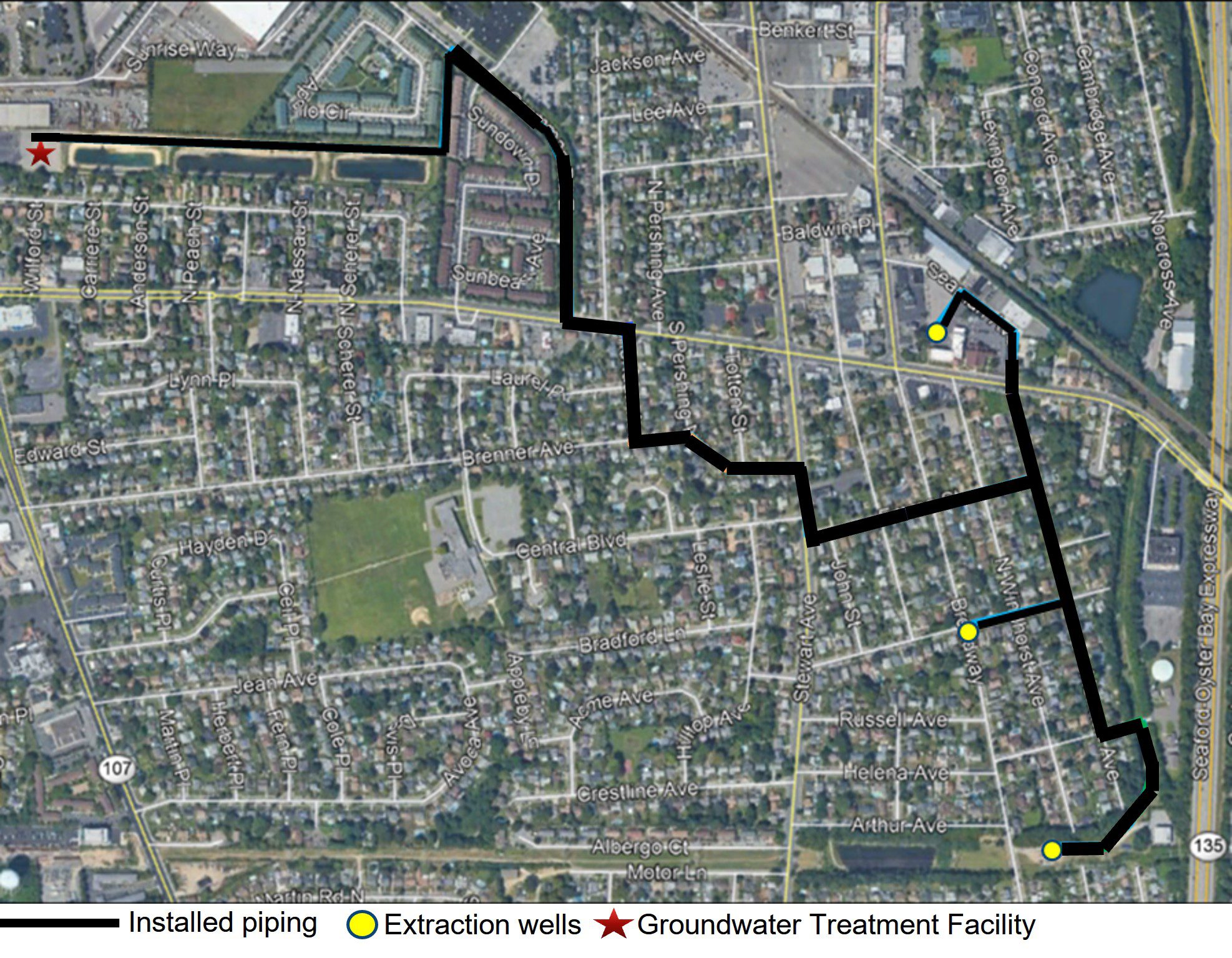

Grumman recently completed a number of projects to remediate the site. An in-site thermal remedy that heats the soil to release and capture vapors was finished at the Bethpage Community Park ballfield, exceeding the state’s cleanup criteria. Additionally, 11,000 feet (over two miles) of double-walled conveyance piping and three well vaults have been installed to operate Grumman’s three groundwater extraction wells.

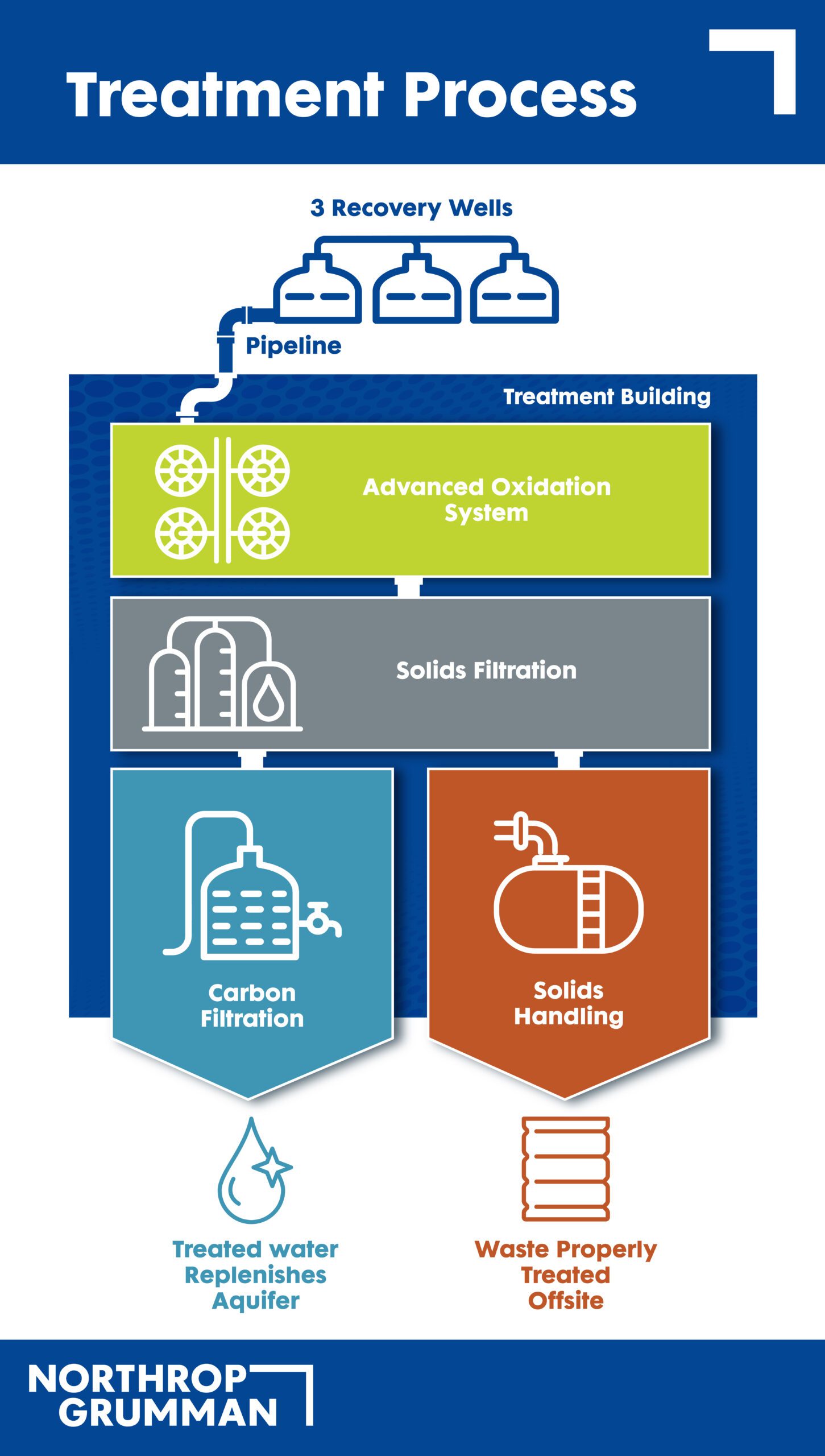

Grumman has also begun construction on a “state-of-the-art” RW-21 groundwater treatment system. “The system will pump up water [from three extraction wells] and carry [it] via the piping to the treatment system building,” Hannon said. “We will treat up to 2.7 million gallons of water a day. We will return the clean water to the aquifer directly below using our three large onsite recharge basins.”

The treatment system should be up and running in October and will operate 24 hours a day, seven days a week. “We’re in a lot better place than we’ve been in the past,” said Mike Boufis, the Bethpage Water District superintendent. “Once this RW21 system gets online, I think that’s the next step to start removing mass out of the plume.”

Although Grumman appears to be making progress, the U.S. Navy is behind schedule, according to Boufis. This is mostly owing to the shortage of materials caused by recent supply-chain issues. “What we’ll see throughout the neighborhoods is they’ll do a little portion, but it’s a little out of sequence because they’ll move to a different location because they have the supplies to do that location versus finishing one,” Boufis said. “I think overall everything’s running considerably smoothly considering what we’re dealing with.”

Grumman has also regularly notified the public about progress on the plume treatment and how construction might affect local residents. According to Hannon, there has been one virtual information session in 2022 thus far, and some 165 updates have been sent to residents throughout the process to date. “We also look forward to the continued dialogue with the residents, business owners and local leaders in our next area of work,” Hannon said. “We will continue to host community sessions and provide ongoing updates to residents and businesses who would like to receive regular communications from our team.”

Full remediation of the plume will take about a century, Boufis said in an earlier Advocate story.

For more information on the cleanup, go to Grumman’s project site.

Scott Brinton contributed to this story.