By Megan Naftali

The semiconductor shortage has stalled production of various technologies, stifling many sectors around the world, including engineering and car sales and service on Long Island.

Semiconductors chips are tiny electrical circuits, in the shape of wafers, with vital components like transistors that make any number of technologies run.

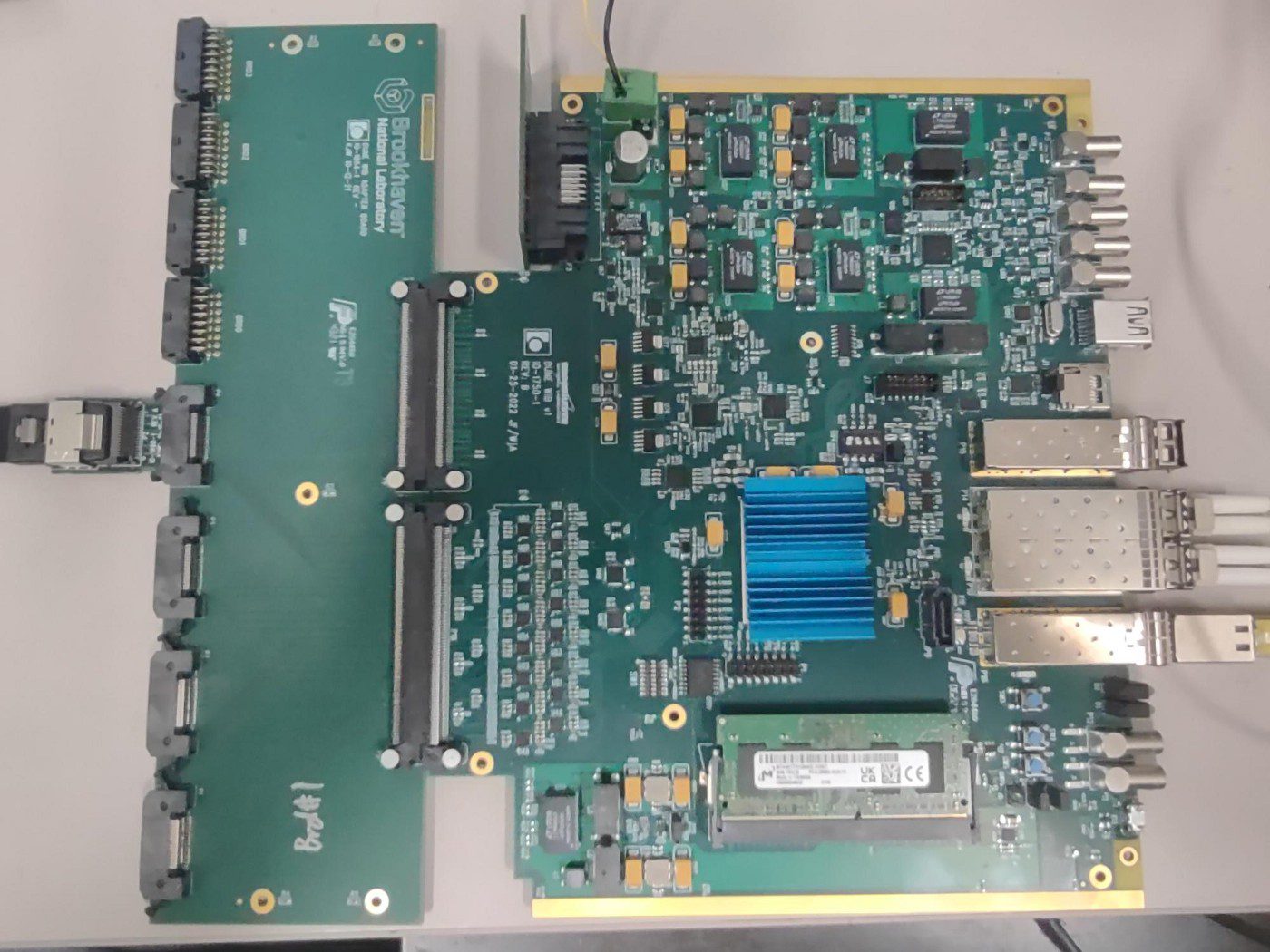

“I produce electronic circuit boards, and my problem right now is due to the fact that I cannot get chips, I cannot produce the boards for the experiments that I work with,” said Jack Fried, an electrical engineer at Brookhaven National Laboratory in Upton, in Suffolk County. “Some of the problems that I run into because I know I can’t get these chips, I have to redesign my electronics to use chips that I can get, which makes my electronics sometimes subpar or lengthens the time it takes for me to produce these boards.”

Jack Fried, a Brookhaven National Laboratory electrical engineer, discussed the chip shortage and the implications for his work and the car industry.

Fried also spoke about how the shortage is affecting the car industry. “Since these chips are used in cars, when they try to build the cars and they’re asking these manufacturers to supply them with chips, they [can’t] build the GPS, they [can’t] build the electronics that control the brakes for your car, and since the shortage, now the assembly lines are shut down, causing issues with getting new cars,” he said.

Terence Lunnon has worked as a sales representative at Autoworld Kia in East Meadow for about a year. He’s been working since the dealership reopened after the Covid-19 lockdowns. Cars have not been coming in as often as they did before the pandemic, according to Lunnon.

“This is a 300-car lot,” he said. “When it comes to new cars, we have only been getting about 100.”

Lunnon shared how selling a car in the current market has become difficult because of the shortage. “In the long run, it’s harder to sell a car because you’re selling it for the value that it is in the market,” Lunnon said. “So because the market went up, it’s a market adjustment, and it’s harder to move vehicles.”

The cost of new and used vehicles has increased, as well. The cost of a car is “at an all-time high,” Lunnon said. “The prices went up 3%, so that’s a nice growth in the profit range.”

Additionally, the chips are used to implement safety features in the vehicles, according to Lunnon. A car made without these chips would not include these features.

“More people are looking to buy cars because it’s harder to get a vehicle, and more people are scared to buy a vehicle because it’s harder to get a vehicle, so more people have their guards up,” Lunnon said.

The shortage is also affecting the car-service industry. Steve Garguilo, the service director at Westbury Jeep, discussed the low supply of keys. The chip shortage “has led to a shortage in supply and a shortage in the ability to produce the vehicles, so it’s sort of a trickle-down [effect] everywhere,” Garguilo said. “We had challenges getting keys for a while. Sales was unable to sell a certain number of cars because they were unable to receive those new cars in their inventory, so it just slowed the process.”

Aside from a lack of keys, the Westbury Jeep service department has had issues obtaining other technologies. “Our technicians rely on Mopar’s Diagnostic Pod to connect to the vehicles electronically and diagnose issues with the vehicle,” Garguilo said. “Due to the global shortages, these pods are unable to be produced as readily as needed, and we have been limited in supplying our new techs with pods and our existing techs with replacements as needed. The cost of these pods had increased significantly as well prior to being limited.”

Garguilo explained why a lack of pods can be an issue for the service department. “Not having enough pods limits our technicians’ productivity when repairing vehicles. All vehicle software updates need to be done through a connected pod, so it slows our repairs down in the shop,” he said. “Chrysler had just come out with a new software on their pods for the new model vehicles prior to this shortage, so only a handful of techs have access to repairing the new models.”

Experts predict that the semiconductor shortage will last for the next two to three years. Samsung Electronics has a $17 billion semiconductor manufacturing plant underway in Taylor, Texas, but it will take time for the parts to make their way into the supply chain once the plant is up and running.

Efforts by Texas to attract the massive $17 Billion Samsung semiconductor chip plant does more than create thousands of good paying jobs and spur our economy.

— Greg Abbott (@GregAbbott_TX) November 27, 2021

It also makes Texas a centerpiece of solving the global supply chain shortage of chips.https://t.co/ryx50HPP7G